제품특징(Characteristics)

제품특징(Characteristics)

Exteriors

Interiors

자동차 내장재용 경량 LWRT 소재

자동차 내장재용 경량 LWRT 소재 친환경 자동차 내장재용 소재 (Door Trim / Package Tray / Headliner 용 소재)

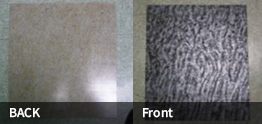

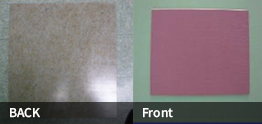

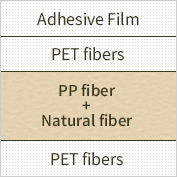

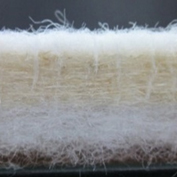

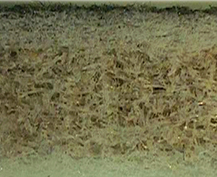

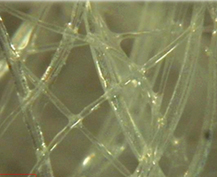

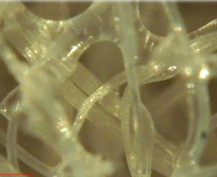

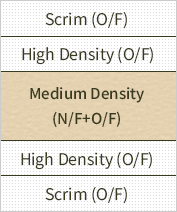

제품 구조 및 특장점

내장재 부품 적용

자동차 외장재용 경량 LWRT 소재

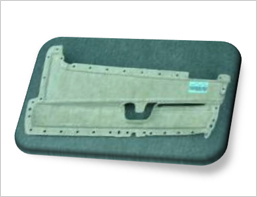

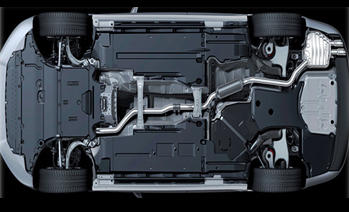

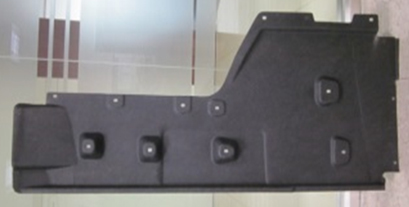

자동차 외장재용 경량 LWRT 소재친환경 자동차 외장재용 소재(Underbody Shield용 소재)

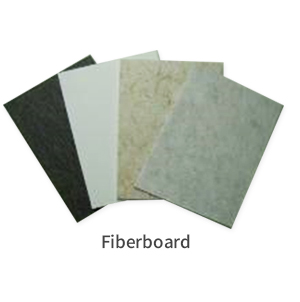

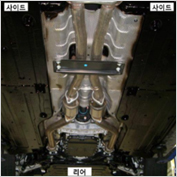

제품 형상

제품 특징

고객사 현황

고객사 현황

공급이력 (Automotive Representative Program History)

공급이력 (Automotive Representative Program History)General Motors

Hyundai Motors

KIA Motors

Chrysler

USA Headliner 적용

USA Headliner 적용

기타 Headliner 적용

기타 Headliner 적용

Door Trim 적용

Door Trim 적용

Package tray (Back Shelf) 적용

Package tray (Back Shelf) 적용

International Truck 적용

International Truck 적용

기타 부품 적용

기타 부품 적용